Titanium Anodizing

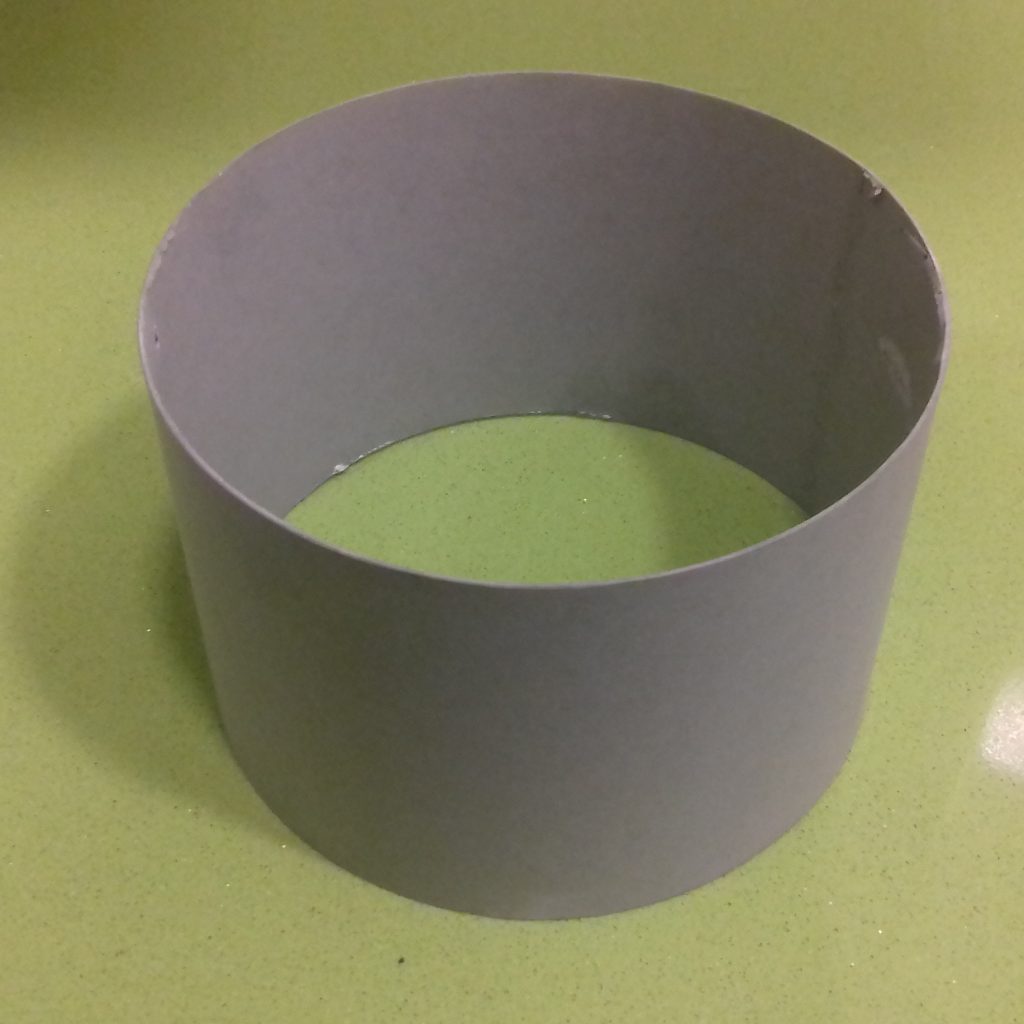

At JGConsulting we have the technology for the anodizing of classic colors with a low thickness layer, such as anodizing for layers of more than 2 microns thick (light grey), both for small parts and large parts, inside tubes, etc.

Titanium anodizing consists of superficial oxidation of titanium, forming oxide layers ranging from 200 nanometers to 900 nanometers, giving colored finishes by light reflection (bronze, blue, yellow, etc.)

Hard Anodizing

Hard Anodizing, sepia grey, gives Titanium a surface hardness of between 700-750 HV. Due to the fact that thicknesses of 1 micron of titanium oxide (TiO2) with a rutile crystalline structure are achieved, osseointegration is improved.

Increases the coefficient of friction and increases the contact surface for better osseointegration. It confers ceramic properties to the treated surface, practically nullifying electrical conductivity, which translates into excellent galvanic protection. Increases resistance to wear.

Organic Anticorrosive Protection

In order to improve the corrosion resistance of metals, we have developed OXYSTOP protection.

OXYSTOP allows metals of all kinds to be kept completely free of oxides, whether they are copper, steel, cut iron, brass, etc., that are highly polished, nuanced, with patinas or aesthetic oxidation, since the layer fixes the patinas preventing them from migrate, due to the effect of rain or contact with hands or clothing.

OXYSTOP confers a completely water-repellent surface, which makes it ideal for the protection of building facades, since by repelling water it extends the clean appearance of the treated surfaces.

OXYSTOP has been tested and certified by the Chair of Corrosion of the Polytechnic University of Catalonia (UPC) resulting in a resistance to corrosion in a 5% saline mist chamber of more than 640 hours. Bearing in mind that the automotive industry requires 250 hours for car bodies, we can see that the durability of the protection is extraordinary.

Selective Plating

Selective plating is a technique that we have adapted from the French galvanic masters that allows deposition of metals “in situ” and only in certain areas of a piece without having to bathe the entire piece.

In this way, an ionic exchange is achieved thanks to the flow of electrons that come and go from the electrolyte to the metal surface, giving extreme adherence to the deposited metal and total laminarity without porosity.